- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

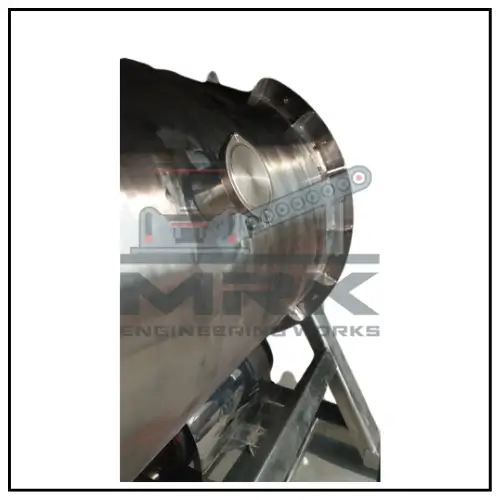

Ball Mills – 2 HP to 25 HP Motor, Stainless Steel for Chemical Industries

Ball Mills – 2 HP to 25 HP Motor, Stainless Steel for Chemical Industries

| Motor Power: | Available in 2 HP to 25 HP motor options, offering power flexibility based on production scale. |

|---|---|

| Material: | High-grade stainless steel construction, ensuring corrosion resistance and easy maintenance. |

| Grinding Media: | Options for using stainless steel balls, ceramic balls, or other media depending on the material being processed. |

| Drum Diameter and Length: | Customizable drum sizes to suit specific batch sizes and production requirements. |

| Capacity: | Variable batch capacities based on drum size, with standard options from 50 kg to 1000 kg per batch. |

| Speed Control: | Adjustable motor speed for precise control over the grinding and mixing process. |

| Voltage: | Standard industrial voltage options (380V-440V, 50/60Hz, three-phase) |

Product Description:

The Stainless Steel Ball Mills are engineered for efficient grinding, mixing, and pulverizing of various materials in chemical industries. Constructed with high-grade stainless steel, these ball mills ensure durability, resistance to corrosion, and long-lasting performance in demanding chemical environments. Available with motor capacities ranging from 2 HP to 25 HP, these mills are suitable for both small-batch production and large-scale industrial operations. Ideal for processing chemicals, powders, and compounds, these ball mills offer a precise and reliable solution for improving material quality and production efficiency.

- Stainless Steel Construction: Provides excellent corrosion resistance, ensuring long-term performance in environments involving chemicals, solvents, and moisture.

Key Features:

- Motor Range: Equipped with motor options ranging from 2 HP to 25 HP, suitable for a variety of production needs, from small batches to continuous operations.

- Stainless Steel Build: The ball mill’s drum and structure are made from high-quality stainless steel, offering durability, resistance to chemicals, and easy cleaning.

- Efficient Grinding and Mixing: The ball mills use a rotating drum and grinding media to grind, mix, and pulverize raw materials into fine powders or consistent mixtures, ideal for chemical processes.

- Variable Capacity: Customizable capacity options to suit different production volumes, making it adaptable to various chemical processing applications.

- Precision Control: Adjustable motor speed and grinding time allow for fine control over the fineness of the output, ensuring optimal results for different chemical formulations.

- Hygienic Design: The stainless steel construction makes these ball mills ideal for applications where hygiene and cleanliness are essential, such as in pharmaceutical or food-grade chemical production.

Application/Usage:

- Chemical Processing: Perfect for grinding chemicals, pigments, and additives, ensuring consistent particle size and uniform mixing in chemical production.

- Pharmaceuticals: Suitable for grinding active pharmaceutical ingredients (APIs) and excipients for precise formulations.

- Powder Processing: Ideal for creating fine powders used in chemical, pharmaceutical, and cosmetic industries.

- Industrial Mixing: Efficiently mixes and blends various chemical compounds for uniformity and consistency in product formulations.

Technical Specifications:

- Motor Power: Available in 2 HP to 25 HP motor options, offering power flexibility based on production scale.

- Material: High-grade stainless steel construction, ensuring corrosion resistance and easy maintenance.

- Grinding Media: Options for using stainless steel balls, ceramic balls, or other media depending on the material being processed.

- Drum Diameter and Length: Customizable drum sizes to suit specific batch sizes and production requirements.

- Capacity: Variable batch capacities based on drum size, with standard options from 50 kg to 1000 kg per batch.

- Speed Control: Adjustable motor speed for precise control over the grinding and mixing process.

- Voltage: Standard industrial voltage options (380V-440V, 50/60Hz, three-phase)

- Liner Options: Optional internal liners for enhanced grinding efficiency and to protect the drum from wear.

Benefits:

- Corrosion Resistance: The stainless steel construction ensures the ball mills are resistant to corrosion, making them ideal for chemical environments that involve corrosive substances.

- Efficient and Precise Grinding: The adjustable motor speed and grinding time allow for precise control, ensuring the desired fineness and uniformity in chemical processing.

- Customizable Power Options: With motor options ranging from 2 HP to 25 HP, these ball mills can handle various production scales and processing requirements.

- Hygienic and Easy to Clean: The stainless steel material is not only durable but also easy to clean, meeting the hygiene standards required in chemical and pharmaceutical production.

- Durability and Long Life: Designed for heavy-duty use, the stainless steel ball mills ensure long-lasting performance, even in harsh industrial environments.

The Stainless Steel Ball Mills with motor capacities ranging from 2 HP to 25 HP are ideal for chemical industries requiring reliable and precise grinding and mixing of materials. With their corrosion-resistant construction and flexible motor power, these mills are suitable for small-scale to large-scale production environments. They provide a durable, efficient, and hygienic solution for a variety of chemical processing applications, ensuring high-quality output and consistent performance.

Related Products

Related products

-

Chemical Industry Related Our Products

Micro Pulverizer – 30 HP Mild Steel for Chemical Industries

₹310,000.00 Add to cartRated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 15 HP Mild Steel for Chemical Industries

₹240,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 7.5 HP Mild Steel for Chemical Industries

₹105,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 30 HP Stainless Steel for Chemical Industries

₹528,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 25 HP Mild Steel for Chemical Industries

₹335,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 120 HP Stainless Steel for Chemical Industries

₹1,530,000.00 Add to cartRated 0 out of 5

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation