- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

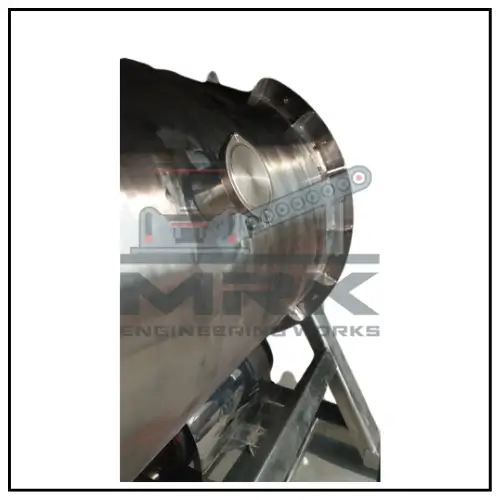

Ball Mills – 2 HP to 25 HP Motor, Stainless Steel for Pharma Industries

Ball Mills – 2 HP to 25 HP Motor, Stainless Steel for Pharma Industries

| Motor Power: | Available in 2 HP to 25 HP motor configurations, offering power options to suit various production requirements. |

|---|---|

| Material: | Made from pharmaceutical-grade stainless steel for compliance with hygiene standards and ease of cleaning. |

| Grinding Media: | Utilizes stainless steel balls, ceramic balls, or other approved media for fine and uniform grinding. |

| Drum Size: | Customizable drum sizes to meet specific batch needs, ensuring flexibility for different production volumes. |

| Capacity: | Batch capacities can be customized, with standard options ranging from 50 kg to 1000 kg per batch. |

| Speed Control: | Adjustable motor speed and timer for precise control over the grinding and mixing process. |

| Voltage: | Standard industrial voltage options (380V-440V, 50/60Hz, three-phase). |

Product Description:

The Stainless Steel Ball Mills are specifically designed for use in the pharmaceutical industry, offering efficient grinding, mixing, and pulverizing of pharmaceutical raw materials and compounds. Built from high-grade stainless steel, these ball mills ensure compliance with industry hygiene standards, offering resistance to corrosion and contamination while maintaining high durability. Available with motor capacities ranging from 2 HP to 25 HP, these mills are suitable for processing small batches as well as large-scale pharmaceutical production, ensuring precise particle size reduction and consistent mixing of active pharmaceutical ingredients (APIs) and excipients.

- Pharmaceutical-Grade Stainless Steel: Ensures hygienic processing, with easy cleaning and full compliance with pharmaceutical manufacturing standards (cGMP).

Key Features:

- Motor Power Range: Available in 2 HP to 25 HP motor options, providing flexibility for small to large-scale pharmaceutical production.

- High-Quality Stainless Steel: Built with pharmaceutical-grade stainless steel, ensuring corrosion resistance, durability, and prevention of contamination, ideal for sterile environments.

- Precision Grinding: Allows for fine particle size reduction, ensuring uniform and consistent grinding, mixing, and pulverizing of raw pharmaceutical ingredients.

- Variable Batch Capacity: Customizable capacities to handle different batch sizes, making it adaptable for both R&D and commercial production.

- Adjustable Speed Control: Offers precise control over the grinding speed and time, enabling customization of the process based on material properties and desired particle size.

- Hygienic Design: Designed to meet strict pharma industry hygiene standards, the equipment is easy to clean and sanitize, ensuring compliance with Good Manufacturing Practices (GMP).

Application/Usage:

- Pharmaceutical Manufacturing: Ideal for grinding and mixing active pharmaceutical ingredients (APIs) and excipients for consistent formulations.

- R&D Laboratories: Suitable for small-batch production and testing in pharmaceutical research and development laboratories.

- Cosmetic Industry: Can also be used for producing fine powders in the cosmetic sector where precision and cleanliness are critical.

- Nutraceuticals: Suitable for the production of dietary supplements and nutraceuticals, where uniform mixing and fine grinding are essential.

Technical Specifications:

- Motor Power: Available in 2 HP to 25 HP motor configurations, offering power options to suit various production requirements.

- Material: Made from pharmaceutical-grade stainless steel for compliance with hygiene standards and ease of cleaning.

- Grinding Media: Utilizes stainless steel balls, ceramic balls, or other approved media for fine and uniform grinding.

- Drum Size: Customizable drum sizes to meet specific batch needs, ensuring flexibility for different production volumes.

- Capacity: Batch capacities can be customized, with standard options ranging from 50 kg to 1000 kg per batch.

- Speed Control: Adjustable motor speed and timer for precise control over the grinding and mixing process.

- Voltage: Standard industrial voltage options (380V-440V, 50/60Hz, three-phase).

- Liner Options: Available with Teflon or stainless steel liners for enhanced grinding efficiency and to protect the drum.

Benefits:

- Pharmaceutical-Grade Construction: The stainless steel design meets the stringent hygiene and safety requirements of the pharmaceutical industry, ensuring no contamination during processing.

- Precision Particle Size Reduction: The ball mills provide precise control over particle size, ensuring uniform consistency in pharmaceutical formulations, which is critical for drug efficacy.

- Versatile Power Options: With motors ranging from 2 HP to 25 HP, the equipment can handle both small-scale production in R&D labs and full-scale manufacturing, making it suitable for various stages of pharmaceutical production.

- Easy to Clean and Maintain: The stainless steel construction and smooth surfaces make it easy to clean, sanitize, and maintain, ensuring compliance with GMP standards.

- Durable and Long-Lasting: Built to withstand continuous use in pharmaceutical environments, the ball mills are durable, resistant to wear, and designed for long-term use.

The Ball Mills – Stainless Steel for Pharma Industries with motor capacities from 2 HP to 25 HP offer a reliable, precise, and hygienic solution for pharmaceutical manufacturing. These mills are essential for grinding, mixing, and pulverizing pharmaceutical ingredients to achieve consistent particle sizes and uniform mixing, ensuring the quality and effectiveness of pharmaceutical formulations. Their durable construction and easy maintenance make them ideal for both R&D labs and large-scale production environments in the pharmaceutical sector.

Related Products

Related products

-

Pharma Industry Related Our Products

Vibro Sifter Machine – 4ft Height Mild Steel for Pharma Industries

₹150,000.00 Add to cartRated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 2ft Height Stainless Steel for Pharma Industries

₹120,000.00 Add to cartRated 0 out of 5 -

Pharma Industry Related Our Products

Ribbon Blender Machine – 5000 kg Capacity, Stainless Steel for Pharma Industries

₹1,300,000.00 Add to cartRated 0 out of 5 -

Pharma Industry Related Our Products

Ribbon Blender Machine – 3000 kg Capacity, Stainless Steel for Pharma Industries

₹1,100,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 25 HP Stainless Steel for Pharma Industries

₹455,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 20 HP Stainless Steel for Pharma Industries

₹350,000.00 Add to cartRated 0 out of 5

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation