- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

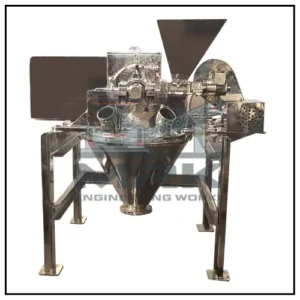

Hammer Mill and Pulverizer – 15 HP Stainless Steel for Chemical Industries

Hammer Mill and Pulverizer – 15 HP Stainless Steel for Chemical Industries

| Material | Stainless Steel |

|---|---|

| Usage/Application | Grinding |

| Brand | MRK |

| Motor | 15 HP |

| Phase | Three Phase |

| Voltage | 380-440V, 50/60Hz |

| Product Type | Single Line Pulverizer |

| Country of Origin | Made in India |

| Dimensions | Customizable based on requirement |

| Capacity | 300-600 kg/hr, depending on material type and desired particle size. |

Product Description:

The Hammer Mill and Pulverizer with a 15 HP Stainless Steel motor is a high-performance industrial machine designed for the chemical industry. It is ideal for pulverizing and grinding chemical compounds, minerals, and industrial powders into fine, consistent particles, making it suitable for medium to large-scale chemical processing. Available in Grade 304 or Grade 316 Stainless Steel, this machine offers excellent corrosion resistance and durability, essential for environments exposed to harsh chemicals.

- Grade 304 Stainless Steel: Perfect for general-purpose chemical applications, offering excellent corrosion resistance.

- Grade 316 Stainless Steel: Provides superior protection against chlorides and aggressive chemicals, making it ideal for more corrosive environments.

Key Features:

- Motor Power: 15 HP, providing powerful performance for medium to large-scale pulverizing and grinding tasks.

- Construction Material:

- Grade 304 Stainless Steel: Ideal for general chemical applications with high durability and corrosion resistance.

- Grade 316 Stainless Steel: Enhanced resistance to chlorides and corrosive chemicals, perfect for more aggressive environments.

- High-Capacity Grinding: Capable of processing large quantities of materials, ensuring efficient and continuous operation.

- Hammering Mechanism: Advanced hammer action ensures uniform pulverization, delivering fine, consistent particle sizes essential for chemical formulations.

- Adjustable Particle Size: Customizable particle size settings for fine powders or coarser materials, depending on the application.

- Automatic Feeding System: Ensures smooth, continuous material flow for uninterrupted production.

- Dust Collection System: Integrated dust control ensures a clean and safe working environment, critical for chemical processing.

- Safety Features: Includes overload protection, emergency stop button, and adheres to industrial safety standards for chemical operations.

- Cooling System: Optional cooling system available for heat-sensitive materials to prevent overheating during extended operations.

- Easy Maintenance: Stainless steel construction makes cleaning easy and ensures corrosion-free operation, reducing downtime for maintenance.

Applications in Chemical Industries:

- Pulverizing chemical compounds such as pigments, resins, and polymers.

- Grinding minerals like calcium carbonate, silica, and talc.

- Fine grinding of pharmaceutical ingredients and cosmetic raw materials.

- Pulverizing fertilizers, pesticides, and other agricultural chemicals.

- Processing raw materials for paints, coatings, and adhesives.

- Handling corrosive chemicals where superior resistance is needed, especially in applications involving chlorides and acids.

Specifications:

- Power: 15 HP

- Material:

- Grade 304 Stainless Steel for general chemical processing.

- Grade 316 Stainless Steel for corrosive environments requiring high resistance to aggressive chemicals.

- Capacity: 300-600 kg/hr, depending on material type and desired particle size.

- Particle Size Output: Adjustable for ultra-fine powders or coarser materials, depending on application needs.

- Operating Voltage: 380-440V, 50/60Hz.

- Dimensions: Customizable based on production requirements.

- Weight: Approximately 500-700 kg, depending on configuration.

Benefits:

- Durability: Stainless steel construction ensures longevity and resistance to corrosion in harsh chemical environments.

- High Efficiency: High throughput ensures efficient pulverizing of large volumes, maximizing production capabilities.

- Versatility: Suitable for a wide range of chemical materials, offering flexibility in multiple chemical processes.

- Precision Pulverization: Provides uniform and consistent particle sizes, essential for maintaining product quality and formulation consistency.

- Safety and Hygiene: Equipped with dust control, overload protection, and made from hygienic stainless steel components, ensuring safe operation and easy cleaning.

- Low Maintenance: Stainless steel design facilitates easy maintenance and minimizes downtime, ensuring continuous, reliable performance.

This 15 HP Stainless Steel Hammer Mill and Pulverizer (available in Grades 304 and 316) is an excellent solution for chemical industries requiring a high-efficiency machine for pulverizing a wide range of materials, including corrosive chemicals. Its stainless steel build ensures durable, reliable, and long-lasting performance in demanding production environments.

Related Products

Related products

-

Chemical Industry Related Our Products

Micro Pulverizer – 25 HP Stainless Steel for Chemical Industries

₹339,000.00 Add to cartRated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 15 HP Mild Steel for Chemical Industries

₹240,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 7.5 HP Mild Steel for Chemical Industries

₹105,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 42 HP Stainless Steel for Chemical Industries

₹577,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 30 HP Stainless Steel for Chemical Industries

₹528,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 30 HP Mild Steel for Chemical Industries

₹475,000.00 Add to cartRated 0 out of 5

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation