- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

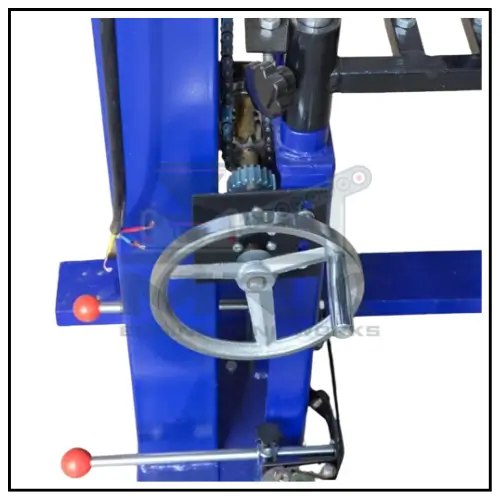

Manually High-Speed Dispenser Machine – 30 HP Motor for Pharma Industries

Manually High-Speed Dispenser Machine – 30 HP Motor for Pharma Industries

| Motor Power: | 30 HP |

|---|---|

| Speed Range: | 0-1450 RPM (adjustable) |

| Material: | High-grade stainless steel construction for corrosion resistance. |

| Operation Type: | Manual control for customized processing. |

| Voltage: | 380-440V, 50/60Hz (three-phase) |

| Capacity: | Suitable for handling small to medium batch sizes, depending on material viscosity. |

Product Description:

The Manually High-Speed Dispenser Machine with a 30 HP motor is designed to meet the stringent demands of large-scale pharmaceutical industries. It ensures precision and uniformity for key tasks like mixing, dispersing, and emulsifying. With a powerful 30 HP motor and a fixed RPM range of 0-1450, this machine is ideal for handling high-viscosity materials and large batch production. The stainless steel construction meets all pharmaceutical-grade hygiene and safety standards, ensuring contamination-free, reliable operations in sensitive cleanroom environments. The manual control allows for full adjustment of speed and processing time to achieve specific batch requirements.

- 30 HP Motor for Pharma-Grade Performance: Designed to provide the power needed for handling large pharmaceutical batches and high-viscosity materials, delivering consistent, high-quality results.

Key Features:

- Motor Power: Equipped with a 30 HP motor, offering robust power for demanding pharmaceutical dispersing, mixing, and emulsifying tasks.

- Fixed RPM Range: Operates at a fixed speed of 0-1450 RPM, ensuring stable, consistent, and controlled performance crucial for pharmaceutical applications.

- Manual Control: Provides full manual control, allowing precise adjustment of speed and processing time to meet specific pharmaceutical production needs.

- Stainless Steel Construction: Built from pharmaceutical-grade stainless steel, offering excellent corrosion resistance, durability, and compliance with hygiene standards.

- Pharma-Specific Applications: Designed for mixing, dispersing, emulsifying, and homogenizing pharmaceutical ingredients, ensuring batch-to-batch consistency and quality.

- Easy Maintenance: Designed for easy cleaning and maintenance, ensuring minimal downtime between batches, critical in pharma environments to prevent cross-contamination.

Application/Usage:

- Pharmaceutical Mixing: Ideal for blending active pharmaceutical ingredients (APIs), excipients, and other components to create uniform, homogeneous mixtures.

- Dispersing Agents: Effectively disperses fine particles into liquids, ensuring smooth, lump-free mixtures in pharmaceutical formulations like creams, gels, and syrups.

- Emulsification: Ensures stable emulsions for pharmaceutical formulations that require mixing of immiscible liquids, such as creams and suspensions.

- Batch Processing: Suitable for large batch production, allowing operators to maintain strict control over process parameters for consistent quality and efficiency.

Technical Specifications:

- Motor Power: 30 HP

- Fixed Speed Range: 0-1450 RPM

- Material: High-quality stainless steel construction, ensuring compliance with pharmaceutical hygiene and corrosion resistance standards.

- Operation Type: Manual control for precise adjustment during pharmaceutical production processes.

- Voltage: 380-440V, 50/60Hz (three-phase)

- Capacity: Designed to handle large batch sizes in pharmaceutical production, making it suitable for medium to large-scale operations.

- Size & Weight: Robust design, suitable for integration into large pharmaceutical production lines and cleanroom environments.

Benefits:

- Powerful Performance: The 30 HP motor provides the power needed to handle high-viscosity materials and large volumes, ensuring efficient and consistent results in large-scale pharmaceutical production.

- Stable RPM Control: The 0-1450 RPM fixed speed guarantees stable and consistent performance, ensuring quality control in every batch.

- Pharma-Grade Construction: Stainless steel construction ensures compliance with the rigorous hygiene standards required in pharmaceutical manufacturing, offering long-term durability and corrosion resistance.

- Manual Precision: Manual control allows operators to fine-tune the speed and duration of processing, ensuring precision and adaptability for different pharmaceutical formulations.

- Low Maintenance: The design facilitates easy cleaning and maintenance, minimizing downtime and ensuring smooth, contamination-free production cycles.

The Manually High-Speed Dispenser Machine with a 30 HP motor and 0-1450 RPM fixed speed is the perfect solution for pharma industries needing reliable, powerful, and hygienic equipment for large-scale dispersing, mixing, and emulsifying tasks. Built to meet the strict standards of pharmaceutical production, this machine ensures consistent, precise, and contamination-free processing, making it ideal for medium to large-scale batch production in pharmaceutical manufacturing environments.

Related Products

Related products

-

Pharma Industry Related Our Products

Vibro Sifter Machine – 2ft Height Stainless Steel for Pharma Industries

₹120,000.00 Add to cartRated 0 out of 5 -

Pharma Industry Related Our Products

Ribbon Blender Machine – 5000 kg Capacity, Stainless Steel for Pharma Industries

₹1,300,000.00 Add to cartRated 0 out of 5 -

Micro Pulverizer For Pharma Industries

Micro Pulverizer – 15 HP Stainless Steel for Pharma Industries

₹290,000.00 Add to cartRated 0 out of 5 -

Micro Pulverizer For Pharma Industries

Micro Pulverizer – 10 HP Stainless Steel for Pharma Industries

₹275,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 7.5 HP Stainless Steel for Pharma Industries

₹175,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 42 HP Stainless Steel for Pharma Industries

₹577,000.00 Add to cartRated 0 out of 5

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation