- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

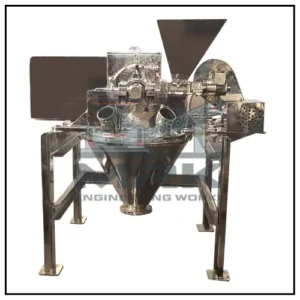

Micro Pulverizer – 10 HP Stainless Steel for Pharma Industries

Micro Pulverizer – 10 HP Stainless Steel for Pharma Industries

| Material | Stainless Steel |

|---|---|

| Usage/Application | Grinding |

| Brand | MRK |

| Motor | 10 HP |

| Phase | Three Phase |

| Voltage | 380-440V, 50/60Hz |

| Product Type | Single Line Pulverizer |

| Country of Origin | Made in India |

| Dimensions | Customizable based on requirement |

| Capacity | 200-500 kg/hr, depending on material type and desired particle size. |

Product Description:

The Micro Pulverizer with a 10 HP Stainless Steel motor is a compact, efficient machine specifically designed for the pharmaceutical industry. It is engineered to finely grind and pulverize pharmaceutical compounds, active ingredients, and excipients into precise, uniform particle sizes, essential for maintaining accuracy in pharmaceutical formulations. Made from Grade 304 or Grade 316 Stainless Steel, this pulverizer ensures superior durability, corrosion resistance, and hygiene, making it ideal for use in pharmaceutical environments where strict cleanliness standards are required.

- Grade 304 Stainless Steel: Suitable for most pharmaceutical processes, providing excellent corrosion resistance and easy maintenance.

- Grade 316 Stainless Steel: Offers enhanced resistance to chlorides, solvents, and aggressive chemicals, making it ideal for environments requiring higher protection.

Key Features:

- Motor Power: 10 HP, providing reliable power for medium-scale grinding and pulverizing tasks in pharmaceutical production.

- Construction Material:

- Grade 304 Stainless Steel: Perfect for general pharmaceutical processing with excellent corrosion resistance.

- Grade 316 Stainless Steel: Provides superior resistance to harsh chemicals and solvents, making it ideal for more corrosive environments.

- Fine Pulverization: Capable of grinding pharmaceutical powders into fine, uniform particles, ensuring consistency in formulations.

- Adjustable Particle Size: Customizable output for producing fine powders or coarser particles based on specific pharmaceutical needs.

- Automatic Feeding System: Ensures continuous material flow, maximizing efficiency in production with minimal downtime.

- Dust Control System: Integrated dust collection ensures a clean, contamination-free environment, meeting pharmaceutical hygiene standards.

- Safety Features: Includes overload protection, emergency stop, and complies with industry safety standards to ensure safe and reliable operation.

- Easy Maintenance: Stainless steel construction allows for quick cleaning and reduces the risk of cross-contamination, ensuring minimal downtime.

Applications in Pharmaceutical Industries:

- Pulverizing active pharmaceutical ingredients (APIs) for use in tablets, capsules, and powder formulations.

- Grinding excipients such as fillers, binders, and lubricants to ensure uniform powder consistency for accurate formulations.

- Pulverizing herbal extracts, vitamins, and nutraceuticals for precise particle sizes.

- Processing ingredients for cosmetics and personal care products.

- Handling pharmaceutical solvents and chemicals, especially where Grade 316 Stainless Steel is necessary for enhanced protection.

Specifications:

- Power: 10 HP

- Material:

- Grade 304 Stainless Steel for general pharmaceutical use.

- Grade 316 Stainless Steel for environments with corrosive substances requiring higher resistance.

- Capacity: 200-500 kg/hr, depending on material type and desired particle size.

- Particle Size Output: Adjustable to produce fine powders or coarser granules, depending on specific requirements.

- Operating Voltage: 380-440V, 50/60Hz.

- Dimensions: Compact and customizable to fit specific production setups.

- Weight: Approximately 350-500 kg, depending on configuration.

Benefits:

- Durability: Stainless steel construction (available in Grades 304 and 316) ensures long-lasting performance and resistance to corrosion, ideal for pharmaceutical environments.

- High Efficiency: Capable of grinding and pulverizing a variety of pharmaceutical materials with continuous, efficient operation.

- Precision Pulverizing: Provides uniform and consistent particle sizes, crucial for maintaining product quality and accuracy in pharmaceutical formulations.

- Hygienic Design: Dust control system and stainless steel construction ensure easy cleaning, minimizing contamination risks and ensuring compliance with pharmaceutical hygiene standards.

- Safety: Equipped with necessary safety features like overload protection and emergency stop, ensuring safe and reliable operation in regulated environments.

- Low Maintenance: Easy-to-clean design reduces downtime, allowing for quick maintenance and ensuring long-term, efficient production.

This 10 HP Stainless Steel Micro Pulverizer (available in Grades 304 and 316) is the perfect solution for pharmaceutical industries requiring precision, durability, and hygiene for grinding and pulverizing pharmaceutical materials. Its robust design ensures reliable, consistent performance while meeting the stringent cleanliness standards required in pharmaceutical production environments.

Related Products

Related products

-

Pharma Industry Related Our Products

Vibro Sifter Machine – 4ft Height Stainless Steel for Pharma Industries

₹190,000.00 Add to cartRated 0 out of 5 -

Micro Pulverizer For Pharma Industries

Micro Pulverizer – 25 HP Stainless Steel for Pharma Industries

₹339,000.00 Add to cartRated 0 out of 5 -

Micro Pulverizer For Pharma Industries

Micro Pulverizer – 15 HP Stainless Steel for Pharma Industries

₹290,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 30 HP Stainless Steel for Pharma Industries

₹528,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 20 HP Stainless Steel for Pharma Industries

₹350,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 15 HP Stainless Steel for Pharma Industries

₹285,000.00 Add to cartRated 0 out of 5

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation