- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

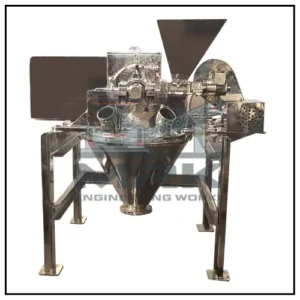

Ribbon Blender Machine – 1000 kg Capacity, Stainless Steel for Pharma Industries

Ribbon Blender Machine – 1000 kg Capacity, Stainless Steel for Pharma Industries

| Material | Stainless Steel (Grades 304/316), providing superior resistance to corrosion and wear. |

|---|---|

| Capacity: | 1000 kg |

| Motor | 7.5 HP |

| Mixing Design: | Double-helical ribbon blade for uniform mixing of materials. |

| Usage/Application | industrial-grade mixing solution designed specifically for pharmaceutical industries. |

| Brand | MRK |

| Phase | Three Phase |

| Voltage | 380-440V, 50/60Hz |

| Country of Origin | Made in India |

Product Description:

The Ribbon Blender Machine with a 1000 kg capacity and 7.5 HP motor is a high-efficiency, medium-scale mixing solution designed for pharmaceutical industries. This machine is engineered for uniform and thorough blending of pharmaceutical powders, granules, and other materials, ensuring consistent and precise mixing across batches. Constructed from Stainless Steel, it provides superior hygiene, corrosion resistance, and durability, making it ideal for handling sensitive ingredients in pharmaceutical environments where strict contamination control is essential. The double-helical ribbon design ensures homogeneous mixing, making it perfect for medium-scale production with a focus on quality and consistency.

- Stainless Steel Construction: Guarantees excellent resistance to corrosion and wear, meeting the hygiene standards required in pharmaceutical production environments.

Key Features:

- Capacity: 1000 kg, suitable for medium-scale pharmaceutical production, providing efficient processing of bulk materials.

- Motor Power: 7.5 HP, delivering reliable and efficient performance for medium-sized blending tasks, ensuring uniform and consistent mixing.

- Gear System: High-torque gear mechanism for smooth, energy-efficient operation, ensuring optimal ribbon blade rotation for consistent blending.

- Stainless Steel Build: Constructed from Stainless Steel (Grades 304/316), offering excellent corrosion resistance, hygiene, and durability.

- Ribbon Design: Double-helical ribbon blades ensure thorough and uniform mixing of materials, eliminating dead spots and providing even distribution throughout the blending chamber.

- Uniform Mixing: Guarantees homogeneous blending of powders and granules, ensuring consistent product quality and uniform formulations in every batch.

- Sealed Construction: Dust-tight design prevents contamination and leakage, ensuring a clean and sterile working environment critical to pharmaceutical production.

- Discharge Valve: Features a manual or pneumatic discharge valve for easy and controlled unloading of blended materials.

- Safety Features: Includes overload protection, emergency stop buttons, and other safety mechanisms, ensuring secure and reliable operation compliant with GMP (Good Manufacturing Practice) standards.

- Easy Maintenance: Stainless steel construction allows for quick and easy cleaning, reducing downtime and ensuring long-term operational efficiency.

Applications in Pharmaceutical Industries:

- Blending of pharmaceutical powders and granules for medium-scale production of medications, supplements, and other pharmaceutical products, ensuring consistency in formulations.

- Mixing of dry and semi-wet materials used in tablet manufacturing, powder blends, and capsules, maintaining product quality across batches.

- Homogenizing bulk pharmaceutical ingredients, ensuring accurate and uniform distribution in medium-sized batches.

- Handling sensitive and reactive ingredients, with stainless steel ensuring hygiene and preventing cross-contamination.

- Preparation of pharmaceutical formulations, ensuring uniform mixing for medium-scale production, ideal for various pharmaceutical products.

Specifications:

- Capacity: 1000 kg

- Power: 7.5 HP motor

- Material: Stainless Steel (Grades 304/316), offering superior hygiene, corrosion resistance, and durability.

- Mixing Design: Double-helical ribbon blades for efficient and uniform mixing of powders and granules.

- Gear System: High-torque gear mechanism ensures smooth and powerful operation for consistent blending.

- Operating Voltage: 380-440V, 50/60Hz (three-phase).

- Dimensions: Customizable to suit specific production needs and space constraints.

- Weight: Approximately 1000-1200 kg, depending on configuration.

Benefits:

- Hygienic Design: Stainless steel construction ensures compliance with pharmaceutical safety and hygiene standards, preventing contamination and ensuring safe handling of sensitive ingredients.

- Efficient Mixing: Double-helical ribbon blades provide uniform mixing, ensuring consistent product quality in every batch.

- Medium Capacity: The 1000 kg capacity allows for efficient production, balancing throughput with precision, making it ideal for medium-scale pharmaceutical operations.

- Low Maintenance: Stainless steel design makes cleaning easy and reduces downtime, ensuring reliable long-term performance in high-demand environments.

- Safety and Cleanliness: Dust-tight construction and built-in safety features like overload protection ensure a clean and secure working environment, compliant with GMP standards.

This Ribbon Blender Machine is an ideal solution for pharmaceutical industries that require medium-scale, uniform blending of powders, granules, and other materials. The stainless steel construction ensures exceptional hygiene, corrosion resistance, and durability, making it perfect for environments handling sensitive pharmaceutical ingredients. With a 1000 kg capacity and 7.5 HP motor, this blender delivers efficient, reliable, and consistent performance for medium-scale production, ensuring compliance with pharmaceutical industry standards for quality and safety.

Related Products

Related products

-

Pharma Industry Related Our Products

Vibro Sifter Machine – 6ft Height Mild Steel for Pharma Industries

₹1.00 Add to cartRated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 4ft Height Stainless Steel for Pharma Industries

₹215,000.00 Add to cartRated 0 out of 5 -

Pharma Industry Related Our Products

Ribbon Blender Machine – 2000 kg Capacity, Stainless Steel for Pharma Industries

₹1.00 Add to cartRated 0 out of 5 -

Micro Pulverizer For Pharma Industries

Micro Pulverizer – 25 HP Stainless Steel for Pharma Industries

₹339,000.00 Add to cartRated 0 out of 5 -

Micro Pulverizer For Pharma Industries

Micro Pulverizer – 15 HP Stainless Steel for Pharma Industries

₹290,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 30 HP Stainless Steel for Pharma Industries

₹528,000.00 Add to cartRated 0 out of 5

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation