- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

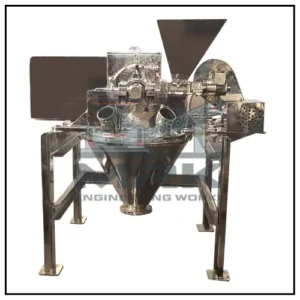

Rotary Airlock Valve – 300 mm Dia Outlet Stainless Steel for Chemical Industries

Rotary Airlock Valve – 300 mm Dia Outlet Stainless Steel for Chemical Industries

| Diameter: | 300 mm |

|---|---|

| Motor Power: | 5 HP |

| Material: | Stainless Steel (Grades 304/316), ensuring high corrosion resistance, hygiene, and durability. |

| Number of Blades: | 6 blades, ensuring efficient material flow and reduced risk of blockages. |

| Lifting Capacity: | 20 to 40 Tons Per Hour (customizable based on operational needs). |

| Operating Voltage | 380-440V, 50/60Hz (three-phase). |

| Country of Origin | Made in India |

Product Description:

The Rotary Airlock Valve with a 300 mm diameter outlet and 5 HP motor is designed for efficient handling of bulk materials such as powders, granules, and fine particles in chemical industries. Made from Stainless Steel, this valve ensures excellent corrosion resistance and durability, essential for managing abrasive and corrosive substances in demanding chemical processes. The valve’s 6-blade rotor provides smooth and consistent material discharge, while maintaining airtight conditions in pneumatic conveying and dust collection systems. This robust solution is ideal for maintaining system pressure and preventing air and material leakage.

- Stainless Steel Construction: Provides superior corrosion resistance, ensuring long-term reliability in chemical processing environments.

Key Features:

- Outlet Diameter: 300 mm, allowing efficient material flow for medium to large-scale chemical production processes.

- Motor Power: 5 HP, providing strong and reliable performance to ensure smooth, continuous material handling.

- Material: Stainless Steel (Grades 304/316), ensuring excellent durability and corrosion resistance, making it ideal for handling harsh chemicals and abrasive materials.

- Number of Blades: 6 blades, designed for uniform discharge of materials, preventing blockages and maintaining smooth operation.

- Lifting Capacity: 20 to 40 Tons Per Hour (customizable based on specific requirements), making it suitable for medium to large-scale chemical production environments.

- Airlock Functionality: Prevents air leakage and maintains system pressure, ensuring optimal performance in pneumatic conveying and dust collection systems.

- Sealed Construction: Dust-tight design prevents contamination and material leakage, ensuring safe and clean chemical processing operations.

- Rotary Design: Provides controlled and consistent flow of powders and granules, reducing material buildup and improving overall system efficiency.

- Easy Maintenance: Stainless steel construction ensures easy disassembly and cleaning, reducing downtime and improving operational productivity.

Applications:

- Pneumatic Conveying Systems: Regulates the flow of powders, granules, and other materials into pneumatic systems while maintaining an airlock, preventing air and material leakage.

- Dust Collection Systems: Controls the discharge of dust and fine particles into collection systems, ensuring system cleanliness and preventing contamination.

- Bulk Material Handling: Ideal for chemical production lines that require precise, consistent discharge of bulk materials.

- Feeding Systems: Suitable for controlled feeding in chemical mixing, batching, and processing applications where corrosion resistance and reliability are critical.

Specifications:

- Outlet Diameter: 300 mm

- Motor Power: 5 HP

- Material: Stainless Steel (Grades 304/316) for superior corrosion resistance and durability in handling harsh chemical environments.

- Number of Blades: 6 blades for efficient and smooth material discharge.

- Lifting Capacity: 20 to 40 Tons Per Hour (customizable based on operational needs).

- Operating Voltage: 380-440V, 50/60Hz (three-phase).

- Construction Type: Heavy-duty stainless steel construction designed for demanding chemical processing environments.

Benefits:

- Corrosion-Resistant Design: Stainless steel construction ensures resistance to corrosion and abrasion, making it suitable for handling abrasive and corrosive materials in chemical industries.

- Smooth Material Flow: The 6-blade rotor ensures uniform and consistent discharge of materials, reducing the risk of blockages and ensuring efficient flow.

- Airlock Efficiency: Prevents air leakage, maintaining system pressure and ensuring optimal performance in pneumatic conveying and dust collection systems.

- High Lifting Capacity: Capable of handling 20 to 40 tons per hour, making it ideal for medium to large-scale chemical production operations.

- Low Maintenance: Stainless steel allows for easy disassembly and cleaning, reducing downtime and ensuring high operational efficiency.

This Rotary Airlock Valve is the perfect solution for chemical industries that require a durable, corrosion-resistant valve for handling abrasive and corrosive materials. With a 300 mm outlet, 5 HP motor, and robust stainless steel construction, it ensures reliable performance in pneumatic conveying and dust collection systems. Capable of handling 20 to 40 tons per hour, this valve offers smooth and controlled material flow, ensuring safety, cleanliness, and efficiency in chemical processing environments.

Related Products

Related products

-

Chemical Industry Related Our Products

Semi-Automatic Masala Pulverizer – 3 HP Mild Steel for Chemical Industries

₹80,000.00 Add to cartRated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 30 HP Stainless Steel for Chemical Industries

₹425,000.00 Add to cartRated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 25 HP Stainless Steel for Chemical Industries

₹339,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 25 HP Mild Steel for Chemical Industries

₹335,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 120 HP Stainless Steel for Chemical Industries

₹1,530,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Chemical Industries

Hammer Mill and Pulverizer – 120 HP Mild Steel for Chemical Industries

₹1,175,000.00 Add to cartRated 0 out of 5

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation