- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

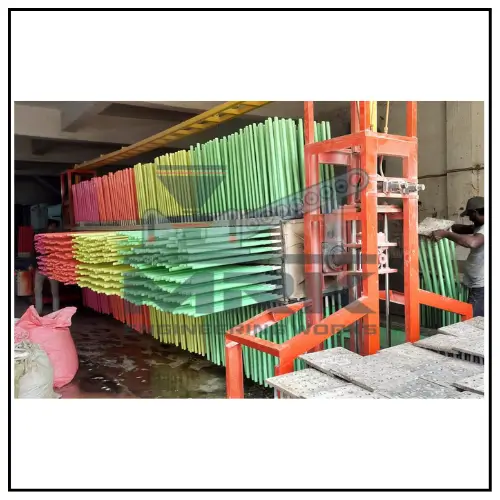

Rubber Band Dipping Machine

Rubber Band Dipping Machine

| Model Name | MRK- Rubber Band Dipping Machine |

|---|---|

| Material | Mild Steel |

| Production Capacity | 300 Kgs in One Batch |

| Power Requirement | 3-phase, 220V/440V |

| Motor | 2 HP |

| Country of Origin | Made in India |

| Applications | Rubber Band Manufacturing |

Category Rubber Band Manufacturing

Product Overview

The Rubber Band Dipping Machine is a high-performance and reliable piece of equipment specifically designed for the production of high-quality rubber bands. This machine streamlines the dipping process, ensuring consistent quality, enhanced productivity, and minimal waste.

Key Features

- High Efficiency: Engineered for fast and continuous operation to meet high production demands.

- Durable Build: Constructed with robust materials to withstand extensive use and deliver long-lasting performance.

- Precision Dipping: Ensures uniform coating for consistent quality across all rubber bands.

- Customizable Settings: Adjustable speed, temperature, and dipping depth to accommodate various production needs.

- Energy Efficient: Designed to minimize energy consumption without compromising performance.

- User-Friendly Interface: Intuitive controls for easy operation and minimal training requirements.

Specifications

- Material: High-grade stainless steel (contact parts)

- Capacity: 200–500 kg/hour (varies with model)

- Power Requirement: 3-phase, 220V/440V

- Machine Dimensions: (Provide dimensions if known)

- Weight: (Provide weight if known)

- Automation Level: Fully automatic / Semi-automatic (as applicable)

- Dipping Mechanism: Vertical/Horizontal (specify)

Applications

- Manufacturing of rubber bands for packaging, stationery, industrial, and personal use.

- Suitable for small-scale to large-scale rubber band production industries.

Benefits

- Enhanced production speed and output.

- Consistent product quality for better market competitiveness.

- Low maintenance costs with a long operational lifespan.

- Eco-friendly design reducing material waste.

Related Products

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation