- Copyright © 1990-2024 MRK Engineering Works By Krunal Enterprise | Website Maintained By KruNetz Design

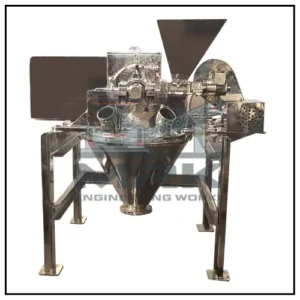

Semi-Automatic Masala Pulverizer – 10 HP Stainless Steel for Pharma Industries

Semi-Automatic Masala Pulverizer – 10 HP Stainless Steel for Pharma Industries

| Material | Stainless Steel |

|---|---|

| Usage/Application | Grinding |

| Brand | MRK |

| Motor | 10 HP |

| Phase | Three Phase |

| Voltage | 380-440V, 50/60Hz |

| Product Type | Single Line Pulverizer |

| Country of Origin | Made in India |

| Dimensions | Customizable based on requirement |

| Capacity | Capable of processing up to 100-200 kg/hour (depending on material being pulverized). |

Product Description:

The Semi-Automatic Masala Pulverizer with a 10 HP motor is an industrial-grade machine designed for the fine pulverization and grinding of raw materials, ideal for use in pharmaceutical industries. Constructed from pharmaceutical-grade stainless steel, this pulverizer ensures high durability, resistance to corrosion, and compliance with GMP (Good Manufacturing Practice) standards. The 10 HP motor provides powerful and efficient grinding, capable of processing large batches of pharmaceutical ingredients such as powders, herbs, and raw materials. Its semi-automatic operation offers ease of use and consistent output, reducing manual labor while maintaining precision and hygiene standards in pharmaceutical production.

- Hygienic Stainless Steel Construction: Ensures safe, contamination-free processing and easy cleaning, adhering to the strict hygiene requirements of the pharmaceutical industry.

Key Features:

- 10 HP Motor: A powerful 10 HP motor delivers efficient grinding performance, making it ideal for large-scale pharmaceutical production.

- Stainless Steel Build: Constructed with pharmaceutical-grade stainless steel, ensuring corrosion resistance, long-term durability, and easy cleaning for hygiene maintenance.

- Semi-Automatic Operation: Allows for controlled material feeding and grinding, ensuring efficient pulverizing with minimal operator effort.

- High Precision Pulverizing: Capable of grinding pharmaceutical ingredients into fine, uniform powders, providing consistent results for formulations.

- Low Heat Generation: Designed to minimize heat buildup during the grinding process, which helps preserve the quality and potency of heat-sensitive materials.

- GMP Compliance: Fully compliant with Good Manufacturing Practices (GMP), ensuring that the machine meets pharmaceutical industry standards for hygiene and safety.

Application/Usage:

- Pharmaceutical Manufacturing: Perfect for grinding and pulverizing active pharmaceutical ingredients (APIs), excipients, and other powder-based materials for medicines.

- Herbal Processing: Suitable for pulverizing herbs, roots, leaves, and other botanical ingredients used in herbal medicines and nutraceutical products.

- Spice and Ingredient Grinding: Can also be used for pulverizing spices and food-grade ingredients used in the production of medicinal and dietary supplements.

- Batch Production: Ideal for medium to large-scale batch production in pharmaceutical manufacturing units and R&D laboratories.

Technical Specifications:

- Motor Power: 10 HP motor providing strong and consistent grinding power for large-scale production needs.

- Material: Built from pharmaceutical-grade stainless steel, ensuring corrosion resistance, durability, and easy maintenance.

- Capacity: Capable of processing up to 100-200 kg/hour (depending on material being pulverized).

- Grinding Fineness: Adjustable fineness settings to achieve powder sizes from 100 to 300 mesh, depending on product requirements.

- Operation Mode: Semi-automatic, allowing for efficient control over material feeding and grinding.

- Voltage: Standard industrial voltage (380V-440V, 50/60Hz, three-phase).

- Safety Features: Equipped with overload protection, emergency stop buttons, and safety locks to ensure secure and safe operation.

- Compact Design: Optimized for use in pharmaceutical production environments, saving space while maximizing output.

Benefits:

- Hygienic and Easy to Clean: The stainless steel construction meets pharmaceutical hygiene standards, making the machine easy to clean and sanitize, reducing contamination risks.

- Powerful Performance: The 10 HP motor provides high grinding capacity, enabling the pulverizer to handle large volumes of material with precision and consistency.

- Precision and Consistency: Adjustable grinding settings ensure that powders and ingredients are ground to a fine, uniform consistency, which is critical for pharmaceutical formulations.

- Durable and Long-Lasting: Built for heavy-duty industrial use, with high resistance to wear, ensuring reliable, long-term operation in demanding environments.

- Energy Efficient: Designed to optimize performance while minimizing energy consumption, reducing operational costs and increasing production efficiency.

The Semi-Automatic Masala Pulverizer – 10 HP Stainless Steel is the ideal machine for pharmaceutical industries looking for efficient, hygienic, and precise grinding and pulverizing equipment. Its stainless steel construction, powerful motor, and compliance with GMP standards make it the perfect solution for processing pharmaceutical powders, herbs, and other materials in medium to large-scale production environments, ensuring consistent and high-quality results.

Related Products

Related products

-

Pharma Industry Related Our Products

Ribbon Blender Machine – 8000 kg Capacity, Stainless Steel for Pharma Industries

₹1,600,000.00 Add to cartRated 0 out of 5 -

Micro Pulverizer For Pharma Industries

Micro Pulverizer – 25 HP Stainless Steel for Pharma Industries

₹339,000.00 Add to cartRated 0 out of 5 -

Micro Pulverizer For Pharma Industries

Micro Pulverizer – 15 HP Stainless Steel for Pharma Industries

₹290,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 30 HP Stainless Steel for Pharma Industries

₹528,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 20 HP Stainless Steel for Pharma Industries

₹350,000.00 Add to cartRated 0 out of 5 -

Hammer Mill and Pulverizer For Pharma Industries

Hammer Mill and Pulverizer – 10 HP Stainless Steel for Pharma Industries

₹215,000.00 Add to cartRated 0 out of 5

Get a Custom Solution for Your Industry

Talk to our experts to find the perfect machinery for your operational needs. Whether you're in the chemical, pharmaceutical, or construction sector, we can customize our solutions to fit your requirements.

Request a Free Consultation