Micro pulverizers are essential machines in the chemical industry, known for their ability to process a wide range of materials efficiently and with precision.

Below, we provide a detailed exploration of their uses, functionality, benefits, and distinctions from standard pulverizers.

What is a Micro Pulverizer Used for in Chemical Industries?

A micro pulverizer is used to process materials into fine powders or particles, a critical requirement in chemical industries for various applications. Here’s how they contribute:

- Size Reduction: Micro pulverizers break down materials into smaller, uniform particles. For example, they are used to grind solid chemicals into fine powders for efficient mixing and reactivity.

- Improved Product Quality: Uniform particle size is essential in producing consistent chemical formulations, whether in pharmaceuticals, fertilizers, or pigments.

- Enhanced Efficiency in Reactions: By increasing the surface area of chemicals, micro pulverizers boost the efficiency of chemical reactions, such as catalysis or polymerization.

- Versatility Across Applications: These machines handle a wide variety of materials, including brittle, fibrous, and slightly sticky substances, making them indispensable for chemical industries.

Common applications include producing fine pigments, grinding resins, creating fertilizer powders, and processing pharmaceuticals.

How Does a Micro Pulverizer Work for Chemical Processing?

The micro pulverizer operates on advanced principles of size reduction, ensuring precision and efficiency. Let’s break down its mechanism:

- Material Feeding: Raw materials are introduced through a hopper, which regulates the flow to ensure uniform processing.

- Impact Grinding: Inside the pulverizer, high-speed rotating components like hammers, blades, or pins strike the material with great force. This impact breaks down larger particles.

- Shear Forces: As the material passes through the grinding chamber, it is further reduced by shear forces generated between fixed and moving surfaces.

- Integrated Classifier: An inbuilt classifier segregates particles based on size. Finer particles pass through a screen or outlet, while larger particles are redirected for additional grinding.

- Collection System: The processed fine powder is collected through a discharge outlet, ready for further applications like mixing or packaging.

This system ensures efficiency, uniformity, and minimal material wastage, which is crucial in chemical processing.

What Are the Key Benefits of Using a Micro Pulverizer in Chemical Industries?

Micro pulverizers offer numerous advantages that make them highly effective in chemical processing:

- Precision and Consistency: These machines deliver highly uniform particle sizes, which is critical for consistent chemical formulations.

- Energy Efficiency: With advanced grinding mechanisms, micro pulverizers consume less energy compared to traditional equipment, reducing operational costs.

- Versatility: They can handle a wide range of materials, including abrasive, fibrous, and slightly sticky substances.

- Compact Design: Despite their powerful functionality, micro pulverizers are compact, saving valuable space in industrial setups.

- Durability: Made from high-quality, wear-resistant materials, micro pulverizers have a long lifespan even when processing abrasive chemicals.

- Improved Product Quality: The fine, homogenous powders produced improve the efficiency of downstream processes like mixing, packaging, and chemical reactions.

What Types of Materials Can Be Processed Using a Micro Pulverizer?

Micro pulverizers are versatile machines that can process a wide array of materials. Some examples include:Organic Materials:

- Pharmaceuticals: Grinding active pharmaceutical ingredients (APIs) into fine powders.

- Food Additives: Processing materials like stabilizers and emulsifiers used in the food industry.

Inorganic Substances:

- Pigments: Used in paints, coatings, and plastics for vibrant colors.

- Catalysts: Fine powders enhance the efficiency of catalytic reactions.

- Minerals: Grinding materials like silica, limestone, and calcium carbonate.

Polymers and Resins:

- Polymers: Pulverizing thermoplastics or thermoset resins into granules for further processing.

Fertilizers:

- Chemical and organic fertilizers are ground into powders for easy application in agriculture.

Dyes and Coatings:

- Processing powders for use in textiles, automotive finishes, and industrial coatings.

How Does a Micro Pulverizer Differ from a Standard Pulverizer?

Micro pulverizers and standard pulverizers serve similar purposes but differ significantly in terms of functionality, design, and applications. Below is a detailed comparison:| Feature | Micro Pulverizer | Standard Pulverizer |

|---|---|---|

| Particle Size Output | Produces ultrafine particles, ideal for micron-level processing. | Produces coarse to medium particles. |

| Speed and Efficiency | Operates at high speeds with integrated classifiers for precision. | Slower operation with less precision. |

| Material Versatility | Can handle complex, abrasive, and fibrous materials. | Suitable for simple, less demanding materials. |

| Applications | Used in high-precision industries like chemicals, pharma, and pigments. | General-purpose use in industries like construction. |

| Classifier System | Includes an integrated classifier for uniform particle distribution. | May lack a classifier, leading to inconsistent sizes. |

| Energy Consumption | More energy-efficient due to advanced grinding mechanisms. | Consumes more energy for the same output. |

| Maintenance Requirements | Requires specialized maintenance for intricate components. | Easier to maintain but less efficient for complex tasks. |

Related Products

-

Chemical Industry Related Our Products

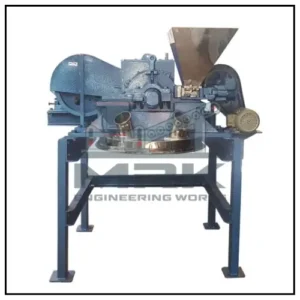

Micro Pulverizer – 30 HP Mild Steel for Chemical Industries

₹310,000.00Rated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 25 HP Mild Steel for Chemical Industries

₹275,000.00Rated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 15 HP Mild Steel for Chemical Industries

₹240,000.00Rated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 10 HP Mild Steel for Chemical Industries

₹190,000.00Rated 0 out of 5 -

Chemical Industry Related Our Products

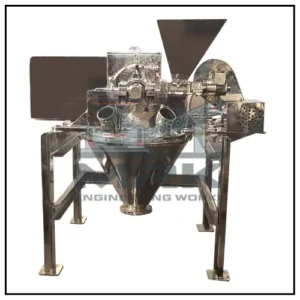

Micro Pulverizer – 30 HP Stainless Steel for Chemical Industries

₹425,000.00Rated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 25 HP Stainless Steel for Chemical Industries

₹339,000.00Rated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 15 HP Stainless Steel for Chemical Industries

₹290,000.00Rated 0 out of 5 -

Chemical Industry Related Our Products

Micro Pulverizer – 10 HP Stainless Steel for Chemical Industries

₹275,000.00Rated 0 out of 5

What Are the Technical Specifications of a Micro Pulverizer for Chemical Use?

Micro pulverizers are designed with advanced features to handle the rigorous demands of the chemical industry. The following technical specifications are typical for a micro pulverizer used in chemical processing:

General Specifications:

- Material of Construction: Stainless steel (SS304 or SS316) for chemical compatibility and corrosion resistance.

- Grinding Mechanism: High-speed rotating hammers, blades, or pins with impact and shearing principles.

- Drive System: Belt-driven or direct-drive motors for consistent performance.

- Motor Power: Typically ranges from 5 HP to 50 HP, depending on the size and capacity.

Performance Specifications:

- Particle Size Output: Capable of producing fine powders with particle sizes ranging from 50 microns to 500 microns.

- Speed: Operates at high speeds, typically between 3,000 to 15,000 RPM.

- Feeding System: Equipped with a vibratory or screw feeder for precise material input control.

- Classifier System: Integrated classifier for uniform particle size distribution.

Operational Features:

- Capacity: Handles material input ranging from 50 kg/hour to 1,000 kg/hour, depending on the model.

- Cooling Mechanism: May include air or water cooling systems to prevent overheating during continuous operations.

- Dust Control: Fitted with dust extraction units or filters to ensure clean and safe working conditions.

Which Factors Should You Consider When Buying a Micro Pulverizer?

Choosing the right micro pulverizer for your chemical processing needs involves evaluating several critical factors:

1. Material Compatibility:

- Ensure the pulverizer is made from materials resistant to the chemicals being processed. Stainless steel (SS304 or SS316) is often preferred for its durability and resistance to corrosion.

2. Desired Particle Size:

- Select a model that matches your required particle size output. Fine chemical applications may demand ultra-fine grinding capabilities (below 100 microns).

3. Capacity Requirements:

- Assess your production scale to choose a pulverizer with the appropriate throughput capacity. Models range from small-scale (50 kg/hour) to industrial-scale (1,000 kg/hour).

4. Power Consumption:

- Compare the motor power and energy efficiency of different models. Lower power consumption machines can significantly reduce operational costs.

5. Maintenance and Durability:

- Opt for machines with wear-resistant components and easy-to-maintain designs to ensure long-term reliability and minimal downtime.

6. Additional Features:

- Look for added features such as cooling systems for heat-sensitive materials, noise-reducing technology, and integrated classifiers for precise particle size control.

7. Budget and ROI:

- Consider the initial cost, operational expenses, and expected return on investment (ROI). A slightly higher initial investment in a quality machine can result in lower long-term costs.

What Is the Capacity Range of a Micro Pulverizer for Industrial Use?

The capacity of a micro pulverizer varies widely depending on the model and application. For industrial use, typical capacity ranges include:

Small-Scale Applications:

- 50 to 200 kg/hour: Ideal for small chemical production units, R&D labs, and specialty applications.

Medium-Scale Applications:

- 200 to 500 kg/hour: Suitable for medium-sized operations producing chemicals like pigments, resins, and dyes.

Large-Scale Applications:

- 500 to 1,000 kg/hour: Designed for high-volume industrial production facilities handling fertilizers, pharmaceuticals, and bulk chemicals.

Custom Solutions:

- Many manufacturers offer customized solutions for capacities exceeding 1,000 kg/hour, tailored to specific industrial requirements.

Can a Micro Pulverizer Process Both Solid and Liquid Chemicals?

Micro pulverizers are primarily designed for processing solid materials, breaking them down into fine powders or granules. However, certain models and configurations can accommodate materials with a slight liquid or moisture content.

Processing Solids:

- Micro pulverizers excel at grinding dry, brittle, or fibrous materials like pigments, resins, fertilizers, and minerals into fine particles.

- They are especially effective in size reduction and homogenization, which are critical for chemical formulations.

Handling Moisture or Liquids:

- While not explicitly designed for liquids, micro pulverizers can handle semi-solid or slightly moist materials with modifications like:

- Specialized grinding chambers to prevent clogging.

- Cooling mechanisms to manage heat generated during grinding.

- For purely liquid chemicals, alternative equipment like colloid mills or homogenizers is more suitable.

What Are the Most Common Applications of a Micro Pulverizer in Chemical Industries?

Micro pulverizers are versatile tools used across various sectors within the chemical industry. Their applications include:

1. Pigment and Dye Production:

- Grinding pigments to fine powders for paints, coatings, and textiles.

- Producing dyes with uniform particle sizes for consistent coloring.

2. Pharmaceutical Ingredients:

- Pulverizing active pharmaceutical ingredients (APIs) to ensure precise dosing in tablets and capsules.

- Grinding excipients for improved drug formulations.

3. Fertilizers:

- Pulverizing organic and inorganic fertilizers to create granules or powders that are easy to distribute.

4. Plastic and Polymer Industry:

- Processing thermoplastics and resins into fine powders for injection molding or extrusion.

5. Catalyst Preparation:

- Grinding catalytic materials to increase surface area for improved reaction efficiency.

6. Specialty Chemicals:

- Processing additives, stabilizers, and other specialty chemicals for industrial applications.

What Is the Maintenance Schedule for a Micro Pulverizer?

To ensure optimal performance and longevity, a regular maintenance schedule is essential. Below is a typical maintenance plan for a micro pulverizer:

Daily Maintenance:

- Inspect the grinding chamber for residue or blockages after every use.

- Check for unusual noises or vibrations during operation.

- Ensure all moving parts are well-lubricated.

Weekly Maintenance:

- Clean the entire machine thoroughly to prevent material buildup.

- Inspect and tighten all bolts and fasteners.

- Check the condition of the hammers, blades, or pins for wear and tear.

Monthly Maintenance:

- Replace worn-out components like screens, liners, and grinding elements.

- Inspect the motor and drive system for alignment and wear.

- Check the cooling or dust control systems for proper functioning.

Annual Maintenance:

- Perform a complete overhaul of the machine, including:

- Replacement of major parts if necessary.

- Comprehensive inspection of all electrical and mechanical components.

- Test the machine’s performance to ensure it meets original specifications.

How to Ensure the Efficiency of a Micro Pulverizer for Chemical Industries?

Maintaining the efficiency of a micro pulverizer is crucial for consistent performance and cost-effectiveness. Here are some strategies to maximize efficiency:

1. Proper Material Handling:

- Ensure the material fed into the pulverizer is within the machine’s capacity and specifications.

- Avoid feeding materials that are too hard, abrasive, or moist without proper preprocessing.

2. Regular Maintenance:

- Follow a strict maintenance schedule (as outlined above) to prevent performance degradation.

- Replace worn-out parts promptly to maintain grinding efficiency.

3. Optimize Operating Conditions:

- Use the pulverizer at the recommended speed and capacity for your application.

- Monitor and adjust the classifier to maintain the desired particle size output.

4. Upgrade Components:

- Invest in high-quality wear-resistant components like hammers, blades, and screens to reduce downtime and improve performance.

- Consider adding a cooling system for heat-sensitive materials.

5. Train Operators:

- Ensure that operators are well-trained in machine operation and safety protocols to minimize errors and maximize productivity.

6. Monitor Output:

- Regularly analyze the particle size and quality of the processed material to ensure it meets specifications.

- Adjust settings like feed rate, speed, and classifier configuration if inconsistencies arise.

Other Products

-

Pharma Industry Related Our Products

Vibro Sifter Machine – 2ft Height Stainless Steel for Pharma Industries

₹120,000.00Rated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 3ft Height Stainless Steel for Pharma Industries

₹150,000.00Rated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 4ft Height Stainless Steel for Pharma Industries

₹190,000.00Rated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 6ft Height Stainless Steel for Pharma Industries

₹270,000.00Rated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 6ft Height Mild Steel for Pharma Industries

₹190,000.00Rated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 4ft Height Mild Steel for Pharma Industries

₹150,000.00Rated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 5ft Height Mild Steel for Pharma Industries

₹160,000.00Rated 0 out of 5 -

Pharma Industry Related Our Products

Vibro Sifter Machine – 3ft Height Mild Steel for Pharma Industries

₹120,000.00Rated 0 out of 5

How Much Does a Micro Pulverizer for Chemical Industries Cost? (India and USA)

The cost of a micro pulverizer varies based on specifications, features, and location of purchase.

India

- Price Range: ₹1.2 lakh to ₹5 lakh (approximately $1,500 to $6,000).

- Entry-Level Models: Machines with lower capacity and fewer features may start at ₹1.2 lakh.

- High-Capacity Models: Advanced models designed for industrial use with features like integrated classifiers or cooling systems may cost up to ₹5 lakh or more.

USA

- Price Range: $10,000 to $30,000.

- Entry-Level Models: Basic pulverizers for smaller operations start at around $10,000.

- High-Capacity Models: Machines with superior build quality, automation, and higher throughput can exceed $30,000.

Shipping and Taxes

- Import duties, shipping, and taxes can significantly affect the final price for international buyers.

What Are the Factors Affecting the Cost of a Micro Pulverizer?

Several factors influence the cost of a micro pulverizer:

1. Material of Construction

- Pulverizers made of stainless steel (SS304 or SS316) are more expensive due to their resistance to corrosion and compatibility with chemical materials.

2. Capacity and Throughput

- Machines designed for higher production rates or continuous operation cost more.

- For example, a pulverizer with a capacity of 1,000 kg/hour will be more expensive than one with a capacity of 200 kg/hour.

3. Features and Add-Ons

- Integrated Classifiers: Provide precise particle size control but increase costs.

- Cooling Systems: Necessary for processing heat-sensitive materials, adding to the price.

- Automation: Machines with advanced control panels or AI-assisted systems are more expensive.

4. Brand and Manufacturer

- Reputed manufacturers often charge a premium for quality assurance, reliability, and after-sales service.

5. Customization

- Tailoring the pulverizer to handle specific materials or meet unique industrial needs increases costs.

6. Regional Factors

- Prices may vary based on local manufacturing costs, taxes, and demand in specific regions.

How Does a Micro Pulverizer Compare to Other Grinding Machines for Chemicals?

Micro pulverizers are one of many grinding machines used in chemical industries. Here’s how they compare to some alternatives:

| Feature | Micro Pulverizer | Ball Mill | Jet Mill |

|---|---|---|---|

| Grinding Mechanism | High-speed impact and shearing | Impact and attrition by rotating grinding media | Compressed air for particle collisions |

| Particle Size Range | 50–500 microns | Down to nanometer scales | Ultra-fine particles (below 10 microns) |

| Material Suitability | Soft to medium-hard materials | Hard and abrasive materials | Heat-sensitive and brittle materials |

| Energy Efficiency | High | Moderate | Low energy efficiency |

| Cost | Moderate | Higher for advanced models | Expensive due to advanced technology |

| Applications | General-purpose, pigments, fertilizers | Pharmaceuticals, ceramics, metals | Pharmaceuticals, fine chemicals, electronics |

Is a Micro Pulverizer Better Than a Ball Mill for Chemical Processing?

Both micro pulverizers and ball mills have their strengths and weaknesses. Here’s a detailed comparison:

Advantages of Micro Pulverizers

- Faster Processing: Pulverizers process materials quicker than ball mills, making them ideal for high-throughput industries.

- Energy Efficiency: They consume less energy due to shorter grinding times.

- Maintenance: Easier to maintain with fewer moving parts compared to a ball mill.

- Versatility: Suitable for soft, brittle, and fibrous materials commonly used in chemical industries.

Advantages of Ball Mills

- Particle Size: Ball mills can achieve finer particle sizes (down to nanometers).

- Material Hardness: Better for grinding hard and abrasive materials.

- Scalability: Available in large sizes for heavy-duty industrial applications.

Which Is Better?

- Micro Pulverizer: Best for applications needing speed, efficiency, and moderately fine powders. Ideal for chemicals like pigments, resins, and fertilizers.

- Ball Mill: Preferred for ultra-fine grinding or when working with extremely hard materials.

Conclusion:

Micro pulverizers are integral to the chemical industry, delivering precise and efficient material processing.

By enabling size reduction, improving particle uniformity, and enhancing chemical reaction efficiency, these machines significantly contribute to product quality and operational optimization.

Their energy efficiency, compact design, and ability to process diverse materials make them indispensable tools in chemical manufacturing.